|

Getting your Trinity Audio player ready...

|

Sublimation printing is gaining more and more popularity with each passing day. It is a type of digital printing that involves the use of specialized paper. It has its pros and cons, but overall it is an amazing process that creates profitable products. So, what is sublimation printing and how to do it? Let’s find out:

What Is Sublimation Printing?

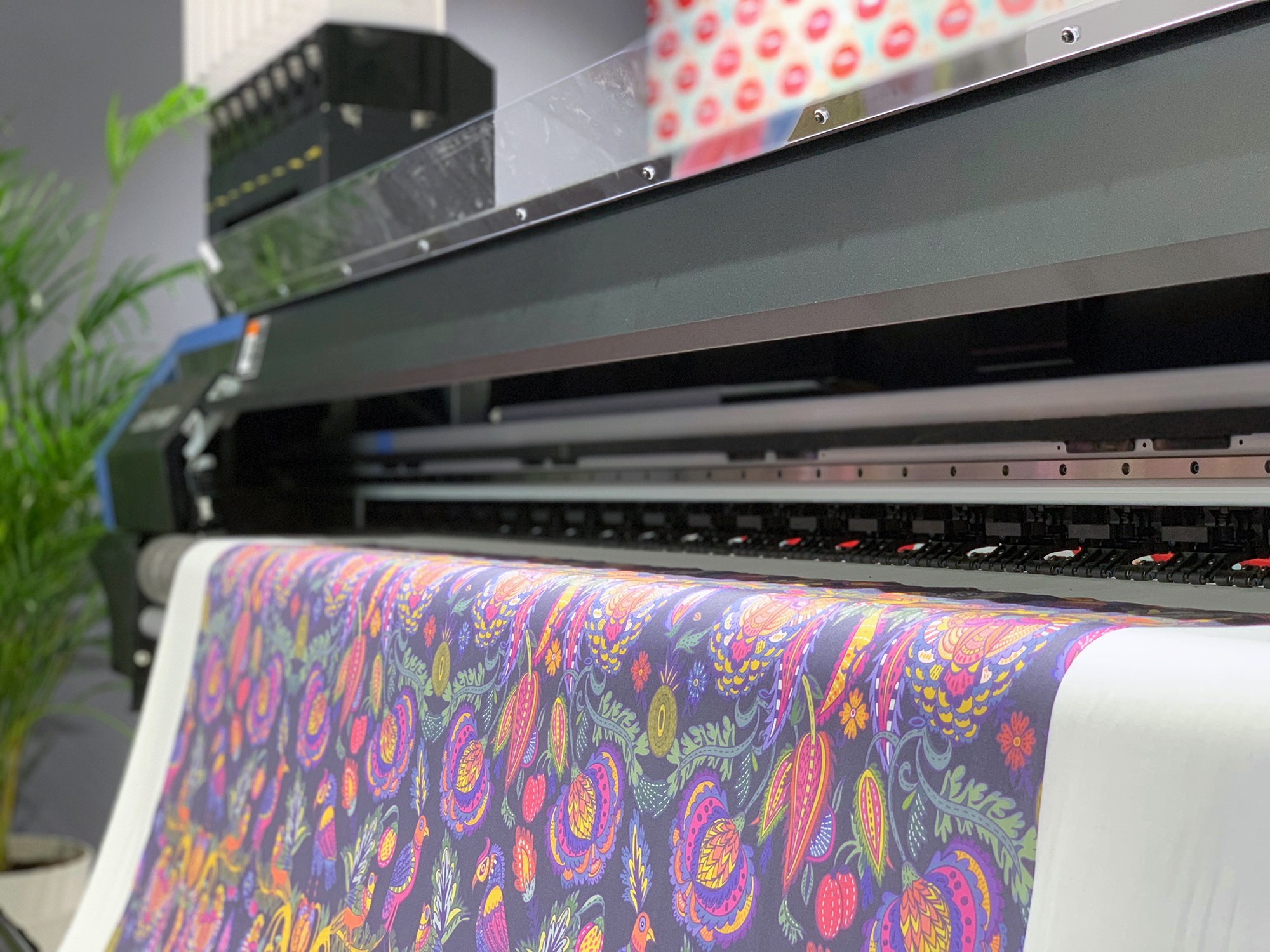

Also called “dye-sub” and “dye sublimation printing”, sublimation printing is a flexible digital printing technique that aids textile designers with their creativity and production output. Sublimation printing is done by transferring the sublimation dyes onto a medium boasting a specially tailored inkjet printer. After the dye is transferred to the medium, they are moved to a heated cloth or object and are pressurised via a commercial heat press.

Sublimation printing is suitable for any object or garment with a polyester coating or polyester base. The dye on the medium undergoes sublimation and transforms into a gas because of heat and pressure, and it is later absorbed by polyester subject to reflect the design.

The finest quality resulting from sublimation printing process does not crack the fabric or fade in colour. Plus, the prints do not have a harsh texture and are very light too. The prints on the sublimation printing t shirts stay bright even after several washes because dye sublimation uses heat sensitive inks.

Suggested Read: Dye Sublimation Of T Shirt Printing

Now, that you know what is dye sublimation printing, let’s move on to how does sublimation printing work:

Sublimation Printing Process

After you chose your design you need to select a sublimation printer. Sublimation printing machines print out designs on to a special paper. Then the design is printed on a fabric by using a heat press or applying pressure and then placing it in the oven.

You need transfer paper to transfer the design to the fabric. The ink is more vibrant in sublimation printing because the ink is embedded by bringing the ink and the fabric together. The pores of the fabric are opened by the heat while the pressure cools the ink which turns it solid. Then the press is releases and the paper is taken off of the mug or shirt gently.

It is a simple process but if it is mastered it can be done at home using a heat press or a compact sublimation.

Sublimation Printing Fabric

Before you start your own printing business, or you do it at home, you need to know the materials you can use:

- Polyester

- Polycotton textile

- PVC

- Polyester-made fabric

- Polymer

- Polymer-coated metal

- Ceramic

- Polyester-coated aluminium

- Polymer- coated plastic

However, there are materials that do not work with sublimation, including 100% cotton materials or other natural materials. This is because they don’t house the pores needed to absorb the ink. So, if you want to work with these materials, go for digital printing.

Also Read: Polyester vs Cotton vs Blends: Which One Is Better?

What Dye Sublimation Supplies You Need?

The first thing you need for dye sublimation is a printer that lets you do sublimation printing and is suitable for sublimation ink cartridges. The second thing you need is a heat press to print the designs on the fabric. For a mug, you will need a mug clamp and press. Another thing you need is transfer paper. You can buy either sublimation or copy paper. Moreover, investing in an RIP software is a good idea to help with colour correction.

Sublimation Printing vs Digital Printing

The main difference between sublimation printing and digital printing is that the latter can print designs on polyester, cotton, and silk while the former is only fit for polyester. Besides, sublimation printing uses heat to transfer the design to the material.

Sublimation printing produces high-quality durable designs, whereas digital printing produces designs that aren’t completely absorbed by the paper which can lead to cracks in the colour. Digital printing is also pricier than sublimation printing.

The type of printing depends on the product you want to create. Both are great types of printing, but it is crucial to weigh the advantages and disadvantages when deciding about your goals and then the printing method will become clear to you.

Also Read: T-Shirt Printing Methods 2021

Advantages and Disadvantage of Sublimation Printing

The Advantages

Durable Designs

Sublimation printing designs do not peel or fade because the ink is absorbed instead of sitting on the top of the fabric like a layer. Hence, you can wash the clothes as many times as you wish to wash them.

Time-Effective

Sublimation printing uses technology, and it can be done faster than other printing methods that need human power. But you still have to monitor it because the heat press has to be accurate, so that the designs are at the same level of quality every time.

High-Quality

Sublimation printing delivers better quality than other types of printing. The vibrancy of the colours and the DPI are particularly impressive depending on the printer you use.

Personalisation

Sublimation printing lets you personalize the size and the quality of the design, and it also gives you the opportunity to fix any mistakes that occur on the printer. This freedom of choice lets you unleash your creativity and make your ideas come to life in a way better than other methods.

The Disadvantages

Colour Mismatch

The design that you create on your computer is displayed in RGB mode, but the printer prints it in CMYK mode. So, the colours do not exactly match the same. To improve this you can adjust the correct settings on your printer or use a RIP software. You need to remember that in all types of printing, even if your image is good in quality, it will not as be as vibrant as it shows on the screen.

Ghosting

Ghosting can happen when the transfer paper shifts during pressing and the print then ends up with a light fade, or it becomes blurry. It happens if the correct amount of pressure is not exerted or if the ink doesn’t dry. To stop this you need to ensure that the ink is dry, and apply the right amount of pressure.

White Creasing

Another drawback of sublimation printing is white creasing. The areas that the design does not reach creates white creases. This can happen if the transfer paper has moisture, or if the garment is folded in any areas, most commonly along seams and under the arms. This results in an unsellable t-shirt.

Also Read: How to Screen Print: A Step-by-Step Guide for Beginners

Conclusion

Sublimation printing is an amazing choice for people who want to create clothes and other items with high-quality graphics and full colour. There is hardly any drawback which ends up in profitable creations. So, if you have ever thought of coming up with designs that are different, then sublimation printing is a creative way to go.

Also Read:

- Screen Printing vs. Dye Sublimation: Which is Better?

- Essential Equipment Needed for T shirt Printing

- Top 5 T Shirt Printing Machines For Small Businesses