|

Getting your Trinity Audio player ready...

|

The t shirt is the most famous piece of clothing used by people of all colours, ages, gender, races and creeds. It is one apparel that unifies all without any distinction. Another reason for its popularity is that it allows custom printing on t shirt as individual self-expression. This quality makes it the superstar of everybody’s wardrobe. The custom printed t shirts are the favourite branding merch for corporate businesses and are widely used to create public campaigns for social development causes like cancer awareness. With this rising admiration, so many artists and designers are exploring the possibilities of starting an online business of custom design t shirt brands. For all t shirts lovers and enthusiasts, we will explore the two types of printing techniques for t shirt printing. We will explore Direct to Garment (DTG) vs screen printing as the focus of this article. We will also compare the qualitative and economical pros and cons of using DTG vs Screen printing methods for custom printing of t shirts.

DTG Vs Screen Printing

We will explain the direct to garment DTG printing and screen printing techniques step by step. Then we will compare the cost, quality and quantity factors both the methods offer for you to choose the best options to opt-in your best interest.

Also Read: 5 Best T Shirt Printing Creative Ideas

Direct To Garment DTG Printing

Let us begin with the process of Direct to garment DTG printing method and technique. DTG printing technique uses water based textile inks that work best on natural and organic fibres like cotton, linen. It requires a curing process of heat press or air conveyor dryers.

Get The Design Ready

Pick a design to print on your custom t shirt; it can be lettering, graphic or a photo image that is digitally generated and ready to go for printing through DTG.

Pretreatment Garment Spray

The pretreatment liquid is sprayed on the t shirt to lock the ink with the fibres of the textile. It is a mandatory pre printing process to enhance the vivid colour, especially before printing white on the coloured fabric.

Press The Garment

Put the pretreated garment through the heat press to flatten the fabric to eliminate any wrinkles on the printable area. Also, a heat press helps the pretreated liquid absorb well and allow the ink to stay well on the garment surface.

Suggested Read: Things You Should Know Before You Buy Heat Transfer Paper

Align The Garment With The Printing Area

Place your t shirt flat and check the design printable area overlapping with the printable rulers. In the case of the dark garment, the layer of printing will create a white background, and then CMYK colours will be printed over it.

Print Cure with Heat Press

This is the last step of the DTG process. You will put your printed garment under the heat press or air conveyor dryer that allows the ink colour to set well and stick firmly with the garment. It also works as a colour sealer for the DTG method.

Benefits Of DTG Printing

Direct-to-garment DTG printing is the simplest solution as it is digital. All you need is a computer, printer and a heat press to get a custom design print on your t shirt. If you want to explore custom printing on a small scale, this is the simplest and most effective way of execution even to initiate your brand.

High-Quality Printing

DTG is super magical when it comes to the minute detailing and printing of multiple colours options. It can generate realistic photo results, and colour variation of hues and shades is unlimited. That gives you all the artistic and creative space to explore your love for designing and printing custom t shirts using DTG.

DTG Is Eco-Friendly

The consumption and wastage of ink are minimal when you use the direct to garment DTG method of printing. It uses water-based inks which are environment friendly and safe to wear for people with sensitive skin types.

DTG Optimized for small to medium Business Scale

Direct to garment DTG printing methods best suit the entry-level and medium-sized business models for custom printing of t shirts. It is a quick automated set-up that helps produce custom printing quality without the wastage of textile ink. It is an efficient business production model to generate an immediate return of investment [ROI] for small and medium-sized productions.

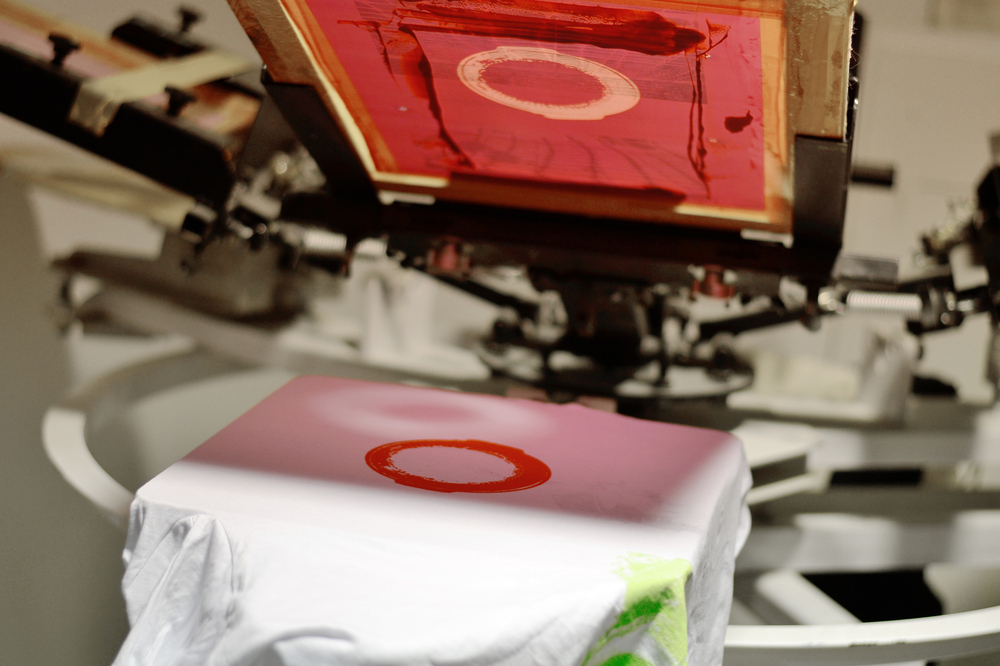

Screen Printing Technique

In the screen printing technique, the ink is pushed through the stencil and absorbs the colour into the fabric’s weave. The screen printing colours are more saturated and vibrant as compared to any other printing method. Let’s see how screen printing works.

Also Read: How to Screen Print: A Step-by-Step Guide for Beginners

Getting Your Design Ready

In the screen printing method, each colour needs to be printed as a separate layer. Traditionally, it is done by making stencils, but now digitally, this separation of paint in layers can be done on photoshop or illustrator that are graphics software.

Read More: Tee Shirt Design Step by Step Guide

Printing Of The Garment

In the screen printing method, a stencil is used to apply a single colour ink, one at a time. That means each colour application needs a separate stencil. The ink is pulled across the stencil using a pressure of pigment blade of foaming tool that prints a single full saturated colour onto the garment.

Type of Design Suitable for Screen Printing

The screen printing is effective for bulk printing and long-lasting quality. It worked best with bold designs and fewer colours, text or graphics. Usually, the primary colour logos on text typography on t shirts are printed for public campaigns and corporate branded events.

Few examples of the events where screen printing is used are charity races, walkathons, mission trips, fundraisers for cancer etc.

Comparison Of Direct To Garment DTG Vs Screen Printing

Now we know the step by step process of Direct To Garment DTG and screen printing separately. Let’s examine the pros and cons of both the printing methods and understand which printing techniques are suitable for whom.

Quality

DTG printing offers unlimited colour options, but the printing quality is faded compared to the screen printing outcome. The DTG printing is not effective when printing lighter colour tones or printing on darker fabric. The print only patches on the fabric in the DTG technique can crack after extended usage and frequent washing.

Screen Printing is the most durable type of printing method as it absorbs the garment’s fibres. Its printing outlook is more saturated and vibrant. However, the printing process is time and labour intensive because of separating each colour by the distinct stencil making. It is the best option for large production and long lasting quality.

Cost

Direct to garment DTG printing is an effective technique for small and medium-size printing orders. The number of colour usage does not affect the printing cost but the time factor increases because one shirt is printed. DTG printing is the best option for custom printing the t shirt, but it will become expensive for the large bulk of orders.

Screen Printing is the cost-effective solution for the larger orders of t shirt printing. The separate stencil making for each colour raises the one time cost. But since it is used for bulk printing of the same design, the overall final cost minimizes essentially.

Final Words

This article addresses the two popular methods of printing that are Direct to garment DTG in comparison to Screen Printing. We are elaborating a step-by-step process of how both techniques work. Later, we draw a comparison of the viability of adopting one method over the other. We also explain the quality and cost-effectiveness of using the DTG or screen printing for small, medium and large printing orders.

Image Source: Shutterstock

Also Read:

- The Complete Guide to Sublimation Printing

- T Shirt Printing & Transfer Paper Types

- The Complete Guide to Sublimation Printing